Steel Production Types – Many North American clients prefer welded steel pipe because it is more affordable, readily available and offers a more consistent thickness. These appealing characteristics of steel are produced by the material used, along with the production methods. The is a main reason why steel is a popular building material around the farm, including modern barns made by top steel building manufacturers.

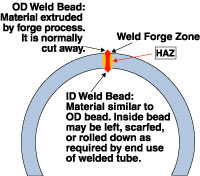

Welded steel pipes are created by taking flat substrates, such as HR coil or a steel plate and shaping then welding them. The pipe is then classified based on the approach used. One thing professionals consider is if the steel pipe is spiral welded or straight seam welded. Others device the material based on the purpose – i.e. manufacturing, agricultural, oil drilling, mining, etc.

One of the most common ways to classify a welded steel pipe is to look at the process used. This means classifying the steel pipes based on the production methods or the sub-processes. The results achieved will fall into one of the three following classifications.

This process is either low or high frequency. It is restricted to a size of (maximum) about 24” in diameter. This welded steel pipe results from the longitudinally welded HR coil.

The primary substrate used in this method is a heavy steel plate. Producers will choose one of the following two methods, which include:

The flat plate that results will have a straight seam stretched the entire length of the pipe. The standard sizes for this pipe option range between 12 and 18m. When this method is used, the quality of the weld is higher and features fewer defects. Steel production types.

This process, just as the name implies, results from a circular motion. The manufacturer will take the plate and wind and weld the substrate of the steel plate or HR coil in a spiral. This is a method that is referred to as helical submerged arc welded (HSAW). The product resulted is much thicker and longer than the other methods. In most cases, this is the preferred method because it is cost-effective, fast, efficient and simple.

Regardless of how a welded steel pipe is classified, the market for distributors and producers is extremely strong. A company that offers a diverse option of welded steel pipes is able to maintain consistent profits. If you are searching for a company to provide you with the welded steel pipe you need, search for one that strives to exceed the expectations of the API regarding quality.

Make sure to contact us with any questions or inquiries!

Website SEO by Pakus Web Services by Pakus Trading Company, LLC.